Coating on Wire (QUREDEO)

Fluoropolymer Coating Onto Ultra-Fine Wires, Bringing Excellent Slipperiness And Operability Widely Adopted For Components In The Medical Industry, Etc.

![Constantly Uniform Coating Film Formation [Development of ”R to R Manufacturing Process” technology] / Highly Adherent Even Metal-Free [Newly developed ”Metal-Free Primer”] /Excellent Responsiveness and Operability [Optimized Balance Between Static and Dynamic Frictions]](../../img/prodoct/quredeo/img01.png)

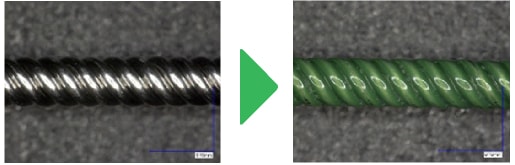

Constantly Uniform Coating Film Formation

We have developed our original processing technology and equipment to achieve uniform coating film formation on element wire. This achieves a uniform slipperiness throughout the entire length of the element wire at any point.

Highly Adherent Even Metal-Free

Our uniquely designed coating materials provide safe and secure products that are highly adherent even metal-free, while a small amount of metal (Cr, Fe, etc.) is generally used to achieve a high adherence in fluoropolymer coatings.

Excellent Responsiveness and Operability

We develop our own design and processing technology for coating materials to achieve an optimal balance between responsiveness (static friction) and operability (dynamic friction).

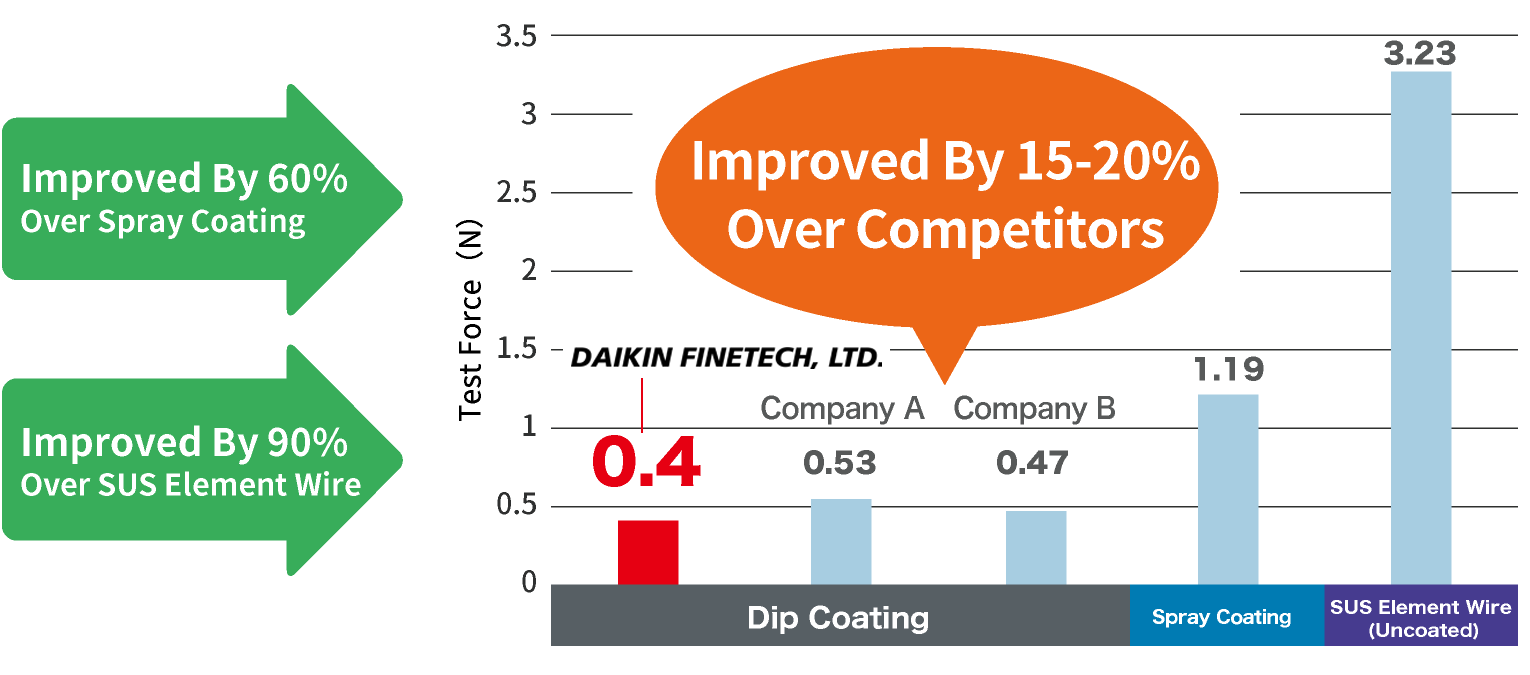

Outstanding Slipperiness

Difference in Slipperiness by Coating Methods (PTFE)

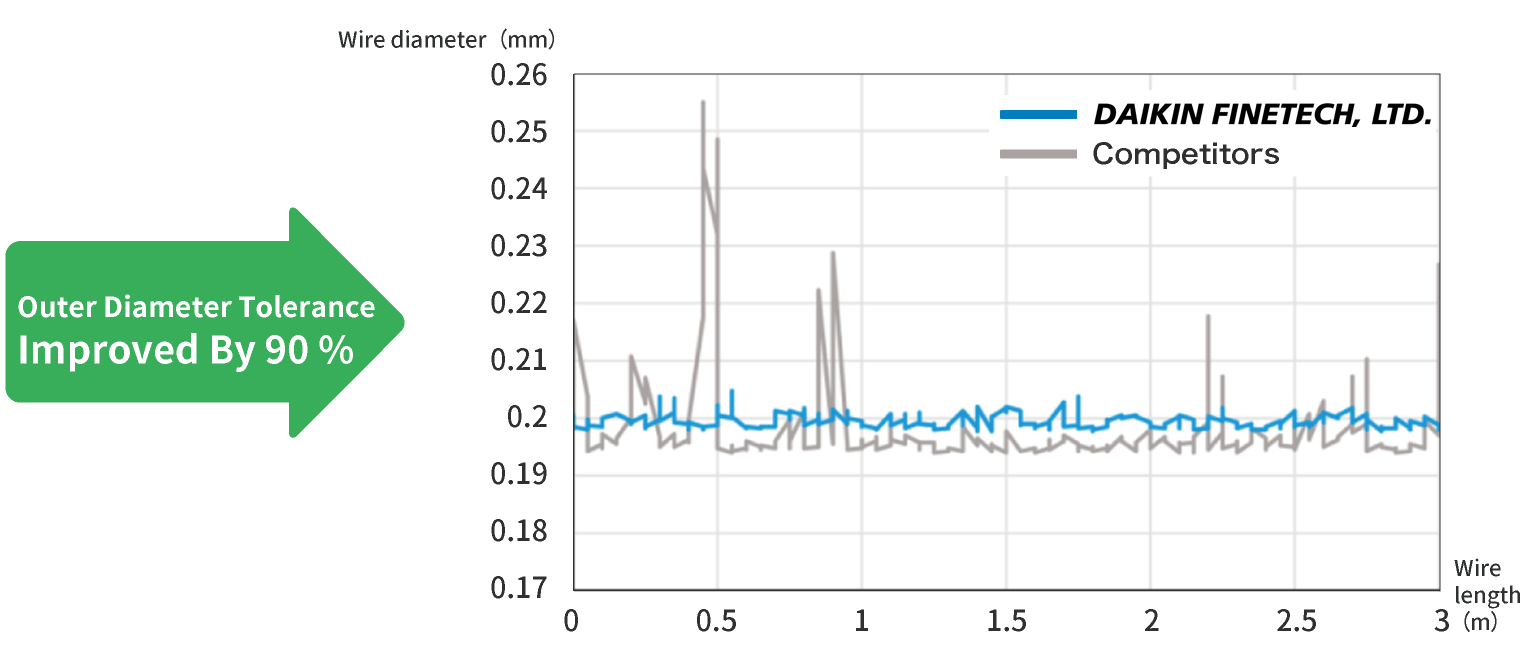

Uniform Coating Film Formation

Comparison Of Outer Diameter Measurement

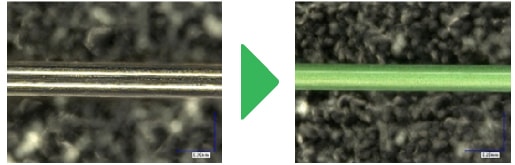

Coating on a Single Wire

Coating on Stranded Wire

Application Examples

- Guidewires (coating on the shaft)

- Various operation wires (push and pull cables, etc.)

- Insulation coating on ultra-thin cables